TEREX WASHING SYSTEMS Washing & Classifying

POA

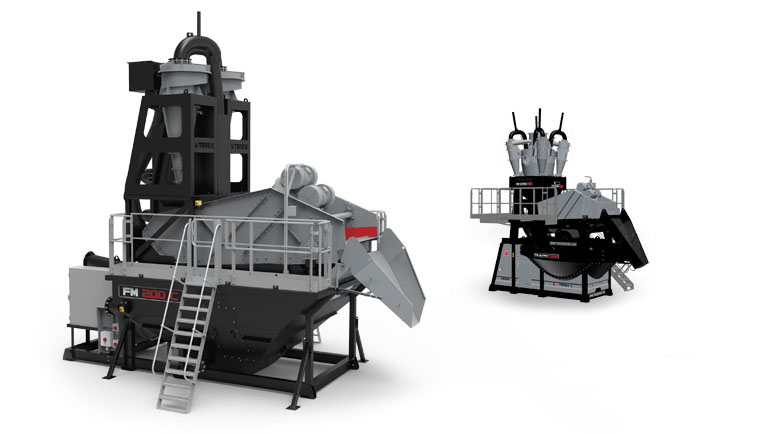

FM Range – Sand Recovery Units

The Terex FM Compact™ range of static sand washing and classification units are designed to be both cost and energy-efficient on a single compact chassis. The range utilises centrifugal force within the hydrocyclone(s) to remove clay, silt and slime from sand to bring it into the desired specification. The range combines a collection tank, centrifugal slurry pump(s), hydrocyclone(s) and a dewatering screen to produce up to 2 clean sands.

- Underflow rubber-lined slurry pump(s).

- Two rubber-lined hydrocyclone(s).

- Self-regulating cyclone tank.

- High-frequency dewatering screen fitted with polyurethane modular mats.

- Maximum recovery of material.

Bucket Wheel Sand Plant – T150

The Terex® T 150 is a mobile bucket wheel dewaterer complete with a fines retention screw and twin bucket wheel designed units to remove clays, silts and slimes to produce up to 2 grades of sand.

The T 150 is designed to operate with maximum versatility and can support different requirements such as maximum retention or maximum disposal of fines. The T 150 can be driven hydraulically from the M Range or its own optional electric power pack.

- Can recover 1 or 2 grades of sand from wet feed or bolt-on boiler box option for direct dry feed.

- High capacity variable speed twin bucket wheel providing increased drainage time for a drier product.

- Deep fluted variable speed fines screw provides excellent fines recovery.

- Anti-turbulence inlet boxes and weir discharge system allows consistently calm settling conditions.

DW Range – Dewatering Screens

Terex Washing Systems offer a range of dewatering screens. Their rugged construction is designed to combat a range of applications.

Whilst primarily applied for dewatering with retained fines, they are capable of being used in a wide range of applications.

The screen incorporates a 45° sloping back deck section fitted with slotted apertures across the direction of flow. The main deck of the screen slopes upwards at 5° vibration and is produced by two exciter motors operating at 980rpm.

- Dewatering screen, catch box and chutes combined onto a single frame.

- Exceptional dewatering performance.

- Modular screen decks.

- Side protection liners.

- Rubber-lined discharge chute.

Sand Screw Plants – SW 100/SW 200/FMW 5434

The Terex® Fines Materials Washers are specifically engineered to provide the highest quality sand production through efficient washing, classification and dewatering. The range consists of 3 models, SW100, SW 200 and the FMW 5434. SW 100 Sand screw is a single screw fine material washer/classifier/dewaterer. The Terex SW 200 is a twin screw fine material washer/ classifier/dewaterer. The FMW 5434 provides unmatched performing serviceability and longevity.

- Heavy duty single or twin dewatering screws (36” x 25”) for high capacity fines recovery.

- Robust, easy-to-assemble steel construction.

- Independent electric drive on each screw for maximum torque under load.

- The all-electric plant can easily integrate with other Terex equipment.

- Low maintenance & simple operation.

Mobile Sand Screw Plants – M 165 S/M 166 S/M 206 S

High-capacity dewatering screws deliver the fine aggregates, while chutes and cross conveyors deliver the sized products. The portable chassis design is easy to transport to the desired site and set up.

- Tripled deck inclined screen produces three grades of washed aggregate and 1 grade of sand.

- Each spray bar has individual flow valves provided for complete water control.

- Heavy duty single or twin dewatering screws (36” x 25”) for high capacity fines recovery.

- Robust I-beam construction chassis with double or triple-axle suspension allows easy transportation and quick set up.

TEREX WASHING SYSTEMS Washing & Classifying

UDC Finance available - Find out more

Specifications & Downloads

PRODUCTS THAT YOU MIGHT ALSO LIKE

TEREX WASHING SYSTEMS Feeding

VIEW PRODUCT

TEREX WASHING SYSTEMS Concrete Washout

VIEW PRODUCT

TEREX WASHING SYSTEMS Greenline Recycling

VIEW PRODUCT